SOFC

SOFC

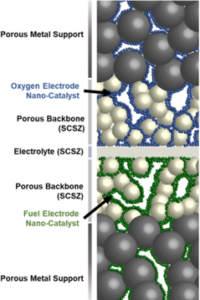

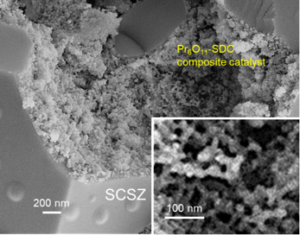

Metal-supported solid oxide fuel cells (MS-SOFCs) contain thin electrolyte and active ceramic layers supported between porous stainless steel layers that provide mechanical strength and electronic current collection. The symmetric-architecture MS-SOFC design developed at LBNL provides cost and operational advantages including: mechanical ruggedness; tolerance to rapid thermal cycling; ability to change operating temperature in response to dynamic load requirements; and, tolerance to oxidation of the fuel catalyst. We are developing MS-SOFCs for applications that require high efficiency and fast-start or intermittent operation, such as personal power generators, residential backup generators, and vehicle range extenders. The focus of research is on cell performance, utilization of hydrocarbon fuels, and scale-up to commercially-relevant cell size.

SOEC

SOEC

Electrolysis uses electricity to drive the efficient conversion of steam, carbon dioxide, etc. to produce hydrogen or other valuable chemicals. We are developing proton-conducting and oxide-conducting metal-supported solid oxide electrolysis cells (MS-SOECs). The vision is to enable utilization of intermittent resources, such as wind- and solar-derived electricity, that may require intermittent operation and adaptation to rapid temperature fluctuations of the SOEC device. The focus of research is on device fabrication, performance improvement, and identification and mitigation of degradation phenomena.

Oxidation Studies

Oxidation Studies

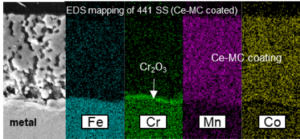

Metallic components of SOFC/SOEC systems oxidize at high temperature during operation. Oxide scale growth degrades system performance, by increasing the electrical resistance of the device, and ultimately by causing mechanical failure of the interface between metallic and adjacent components. We characterize formation of oxide scales in various temperature and atmosphere conditions relevant to SOFC/SOEC operation. The use of coatings to suppress oxide formation is evaluated by monitoring weight gain and resistance during oxidation, and by careful post-mortem analysis.

Solid State Batteries

Solid State Batteries

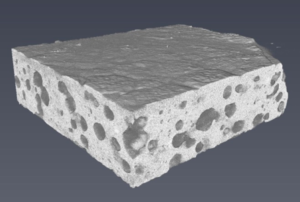

Solid state batteries (SSB) promise higher energy density and safer failure modes compared to conventional Li-ion battery technology. We are developing scalable processing approaches to fabricate SSB electrolyte, electrode, and cell structures using LLZO ceramic powder. These include tape-casting, innovative sintering techniques, and high-throughput processes for producing highly porous LLZO scaffolds. Ultimately, the porous electrodes are filled with active materials to complete the cell. Various diagnostic techniques are used to characterize the interaction between adjacent cell components.

For a summary of previous research projects, please see Mike Tucker’s page.