Mike Tucker

Staff Scientist

mctucker@LBL.gov

510-486-5304

LinkedIn Profile

Google Scholar Profile

Tucker Lab

Mike Tucker develops electrochemical devices at all stages from inception to fabrication, diagnostics, and analysis. His research activities focus on resource-efficient development of new devices and concepts, with a clear focus on using fundamental research to develop viable technology. In-situ electrochemical testing, advanced diagnostics, and post-mortem analysis are used to determine limitations to cell performance and lifetime and inform efforts to improve device performance metrics, cost, and manufacturability. Much of Tucker’s research is sponsored by or in collaboration with industrial partners. In addition to hands-on technical R&D, Tucker’s entrepreneurial activities are also focused on moving technology out of the Lab and into the marketplace. He has authored many patents, co-founded a start-up company, led technology transfer to industrial partners, and led Customer Discovery efforts for various Berkeley Lab and Cyclotron Road technology teams.

Recent Honors and Awards

LBNL Director’s Award for Exceptional Achievement in Technology Transfer

R&D 100 Award for Point Source Power’s VOTO product

ProtoLabs “Cool Idea” Award for VOTO product

Berkeley Center for Entrepreneurship and Technology, Clean Technology Innovation 1st Prize

Education

2002, Postdoc Materials Chemistry, Uppsala University, Sweden

2001, Ph.D. Chemical Engineering, UC Berkeley

1997, B.S. Chemical Engineering, Brown University

Entrepreneurial Experience

Point Source Power was spun out of LBNL to commercialize metal-supported SOFC personal power products for the millions of developing world households that cook with charcoal. Mike was co-Founder and CTO, and had responsibilities in cell development, product development, and prototyping for field trials.

Point Source Power was spun out of LBNL to commercialize metal-supported SOFC personal power products for the millions of developing world households that cook with charcoal. Mike was co-Founder and CTO, and had responsibilities in cell development, product development, and prototyping for field trials.

hi-Lyte Power was co-founded by David Lambelet (Mike’s previous mentee at LBNL) to commercialize the low-cost battery for the developing world that Mike invented and prototyped in the Weber Lab [link to Adam’s site]. Mike serves as Technical Advisor, with contributions in customer discovery, building relationships with technical and market experts, and technical direction.

hi-Lyte Power was co-founded by David Lambelet (Mike’s previous mentee at LBNL) to commercialize the low-cost battery for the developing world that Mike invented and prototyped in the Weber Lab [link to Adam’s site]. Mike serves as Technical Advisor, with contributions in customer discovery, building relationships with technical and market experts, and technical direction.

Customer Discovery: Following the Lean Startup approach to developing product-market fit, Mike has helped various technical teams refine their value proposition with customer interviews, ecosystem mapping, business model canvas generation, and Customer Discovery strategy.

Technology Transfer: With the goal of assisting industrial partners in the development and commercialization of LBNL IP and technology, Mike has led Tech Transfer efforts. These include hands-on teaching of LBNL processes and know-how, development of manufacturing documentation, and detailed seminars on LBNL’s technology development.

Previous research projects

Highlights of several past research efforts are provided below. For an overview of active research areas, please see the Tucker Lab page [link to tuckerlab research]

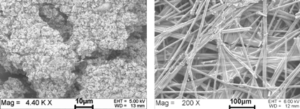

MS-SOFC: Metal-supported Solid Oxide Fuel Cells are rugged, cost-effective cells that are well-suited for portable and mobile applications requiring abuse tolerance, rapid start-up capability, and fuel flexibility. LBNL has been a leader in this field since the early 2000’s. Mike was the key hands-on developer from 2004 to 2016, wrote the first comprehensive review of the field in 2010, and now leads the effort.

MS-SOFC: Metal-supported Solid Oxide Fuel Cells are rugged, cost-effective cells that are well-suited for portable and mobile applications requiring abuse tolerance, rapid start-up capability, and fuel flexibility. LBNL has been a leader in this field since the early 2000’s. Mike was the key hands-on developer from 2004 to 2016, wrote the first comprehensive review of the field in 2010, and now leads the effort.

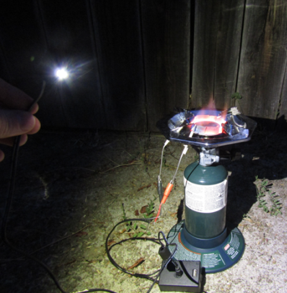

MS-SOFC VOTO: The VOTO utilizes charcoal fuel to produce electricity while cooking. During a typical cooking session, enough energy is produced to charge a mobile phone or for a couple nights of LED lighting. Units were field tested with end-users throughout Kenya. (Point Source Power)

MS-SOFC VOTO: The VOTO utilizes charcoal fuel to produce electricity while cooking. During a typical cooking session, enough energy is produced to charge a mobile phone or for a couple nights of LED lighting. Units were field tested with end-users throughout Kenya. (Point Source Power)

MS-SOFC Camping Power: Following inspiration from PSP’s HALO propane generator, an integrated design for fuel cell stack, LED driver circuitry and stable USB power port was developed and prototyped. The MS-SOFCs sit in the flame of a camping stove, providing the necessary operating temperature and hydrogen + carbon monoxide fuel.

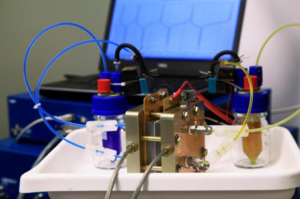

Redox Flow Batteries: Optimization of cell architecture, cell materials, electrolyte compositions, component processing and operating protocols to improve cell performance, efficiency, and cycle-life. The principle systems studied are: hydrogen-bromine, hydrogen-cerium, hydrogen-iron, and chlorate/chloride.

Low-cost battery for the Developing World: Development of a low-cost, non-toxic battery composed of off-the-shelf components that can be safely disposed of after use. The primary active materials are iron foil and ferric sulfate. The user assembles the components before use, adds water to dissolve the catholyte salts, and uses the battery for LED lighting or cell-phone charging. Our group invented this technology and produced consumer product prototypes in conjunction with the UCB Capstone engineering program. (Technology transferred to hi-Lyte Power)

PEM fuel cells: Assisted the Weber group with diagnostics development and cell testing.

PEM fuel cells: Assisted the Weber group with diagnostics development and cell testing.

Ceramic filter: Developed an improved SiC filter for molten iron foundry applications. Enhanced strength, functionality, and appearance by application of thin glass and glass/ceramic coating throughout the reticulated filter porous structure. (Funded by Foseco/Vesuvius)

Ceramic filter: Developed an improved SiC filter for molten iron foundry applications. Enhanced strength, functionality, and appearance by application of thin glass and glass/ceramic coating throughout the reticulated filter porous structure. (Funded by Foseco/Vesuvius)

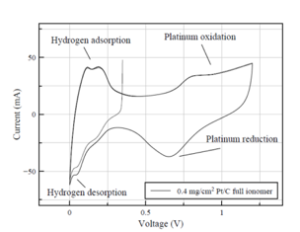

DMFC: Determined impact of manufacturing processes on detailed pore structure of catalysts, electrodes, and gas diffusion layers, and related structural changes to cell performance. (Uppsala University)

DMFC: Determined impact of manufacturing processes on detailed pore structure of catalysts, electrodes, and gas diffusion layers, and related structural changes to cell performance. (Uppsala University)

NMR Studies of Li Battery Materials: Utilized 7Li nuclear magnetic resonance to investigate the origins of capacity fade in LiMn2O4 spinel cathode materials. Fabricated and cycled cells with a wide variety of dopants on the Mn site, and correlated structural changes after cycling with model degradation processes. (U.C. Berkeley)

NMR Studies of Li Battery Materials: Utilized 7Li nuclear magnetic resonance to investigate the origins of capacity fade in LiMn2O4 spinel cathode materials. Fabricated and cycled cells with a wide variety of dopants on the Mn site, and correlated structural changes after cycling with model degradation processes. (U.C. Berkeley)